Complete Bag-in-Box Packaging, Cartoning, and Palletizing Line

Advanced and fully automatic bulk packaging systems, including bag-in-carton placement, bag filling, sealing and vacuuming, carton closing, filling plastic buckets, and final palletizing with high accuracy and speed for a wide range of products.

/Tab-13-Proj-6-Bulk & Specialized Packaging (Bag-in-Box, Big Bags)-Product.png)

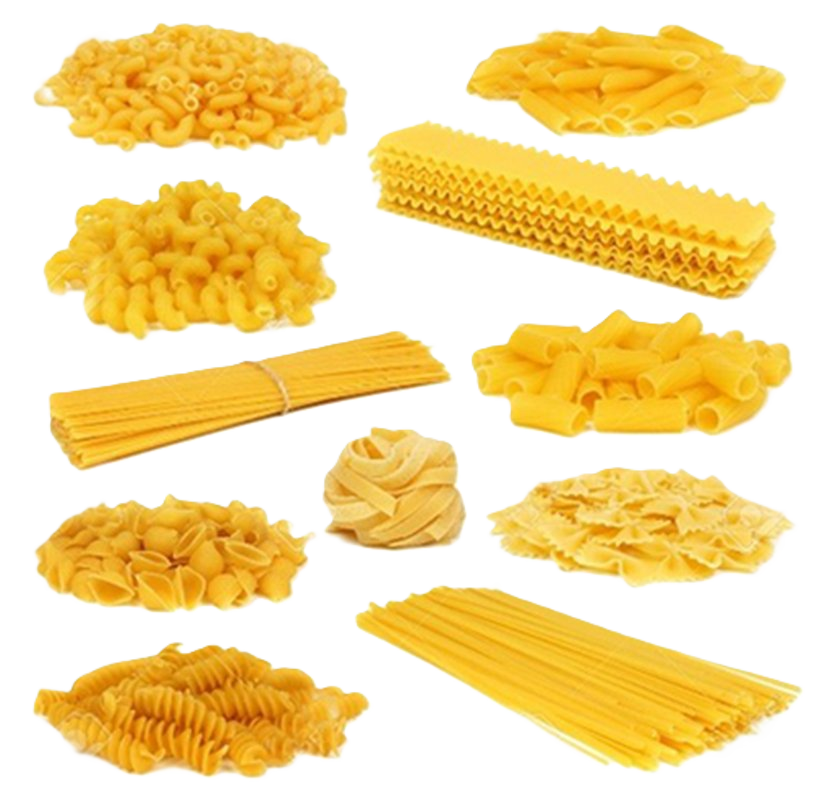

Types of products that can be packaged:

- Nuts and kernels (walnuts, almonds, pistachios, etc.)

- Dates and dried fruits (raisins, figs, apricots, etc.)

- Frozen fruits and vegetables

- Frozen meat, poultry, and fish

- Bread, croissants, and bakery products

- Margarine and shortening

- Tobacco and similar products

Production capacity (depending on product weight and type):

- Bread: 10,000 loaves/hour, 12,000 baguettes/hour, 80,000 rolls/hour

- Layered pastries: 24,000 to 200,000 products/hour

- Nuts: 10–12 cartons/minute (depending on carton size)

- Margarine and shortening: 18–24 tons/hour

- Frozen fruits and vegetables: up to 10 cartons/minute

An ideal choice for exporters and manufacturers seeking higher productivity, space optimization, energy efficiency, high flexibility for rapid product and packaging size changes, premium packaging quality, and competitive advantage in domestic and export markets.

Process Flow Diagram

/Tab-13-Proj-6-Bulk & Specialized Packaging (Bag-in-Box, Big Bags)-Line.png)

For more information and consultation on setting up a production line, contact us today.

.png)

_800px.png)

_800px.png)

.png)

-copy.png)