Ready-to-Eat Meal Kit Production & Packaging Line

The rapid growth of busy lifestyles has made ready-to-eat Meal Kits one of the fastest-growing segments in the food industry. These products combine fresh, pre-prepared ingredients, allowing consumers to prepare a healthy, delicious meal in minimal time.

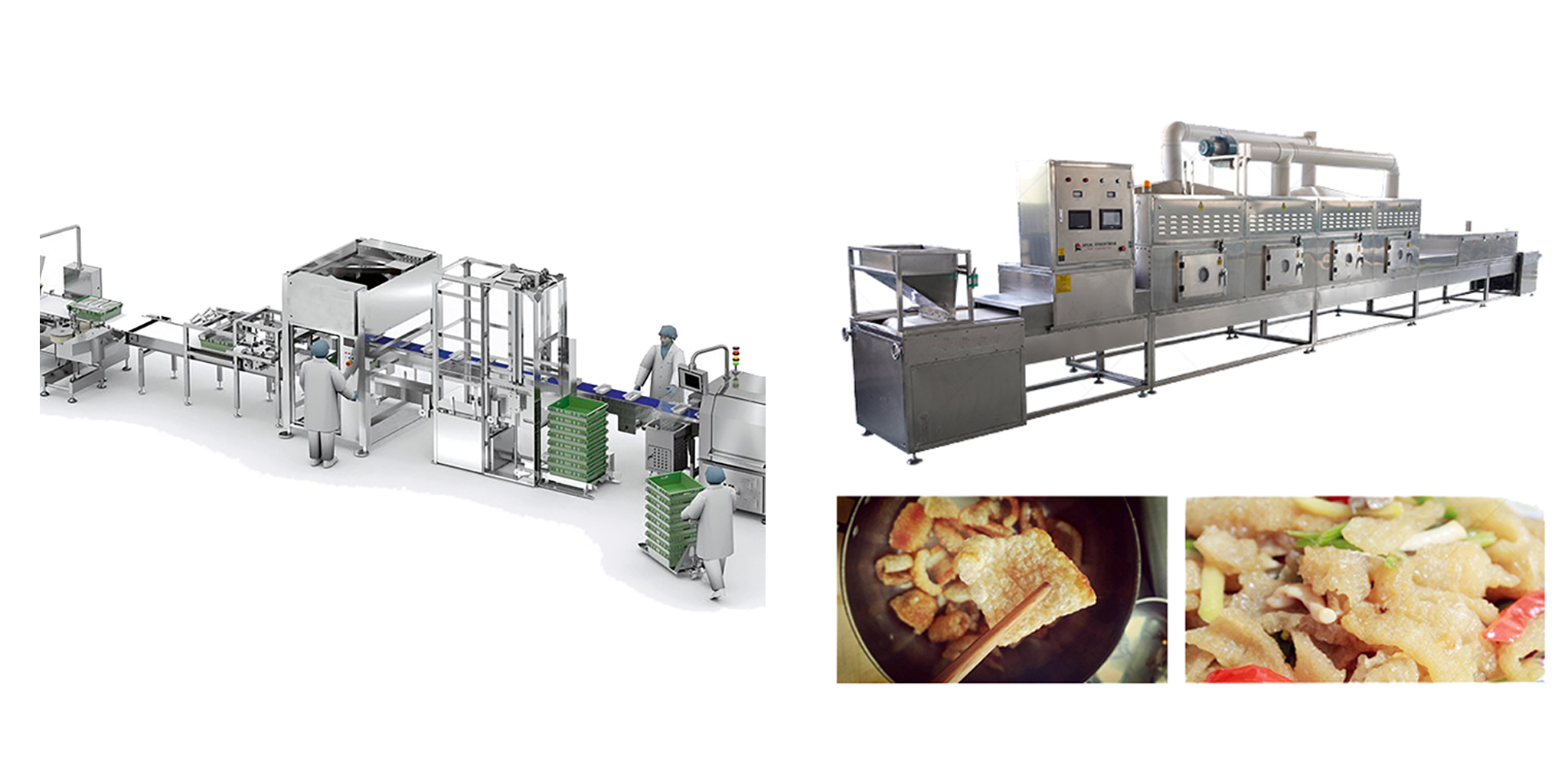

Proposed production process:

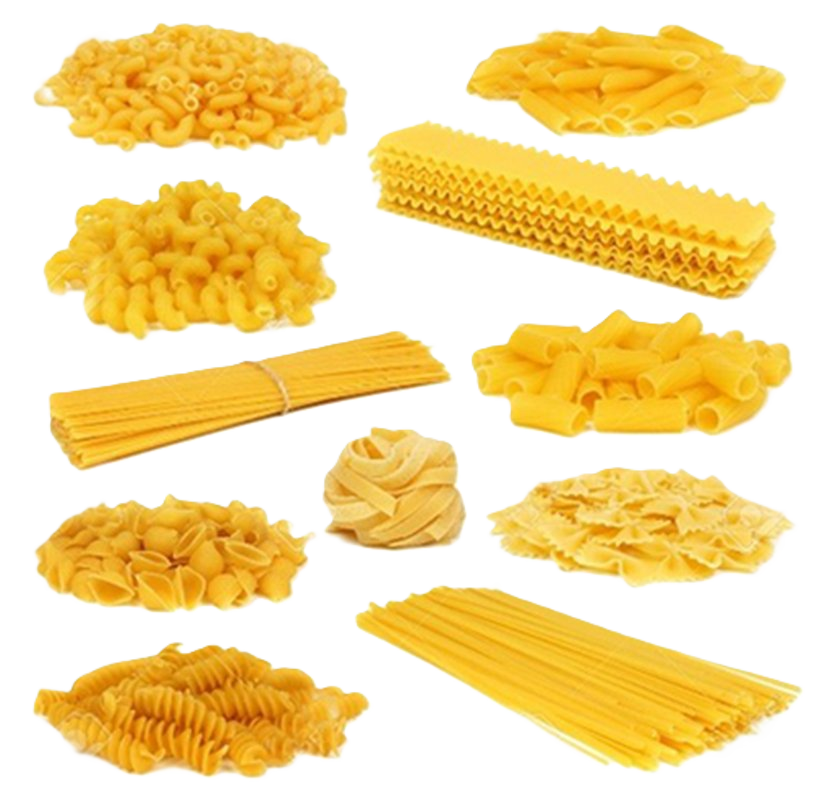

- Preparation of ingredients: Washed and chopped vegetables, proteins (chicken, fish, meat, or plant-based options), pasta, rice or grains, along with ready-made sauces and seasonings.

- Weighing & dosing

- Filling into plastic, cardboard, or recyclable containers

- Adding seasonings & condiments in sachets or small packs inside the Meal Kit

- Sealing & closing: Using film or foil to protect against contamination and maintain freshness.

- Secondary packaging: Placing into cartons or family/export boxes.

Production Capacity:

- Single-serve or family-sized Meal Kits: 30–150 packs per minute depending on ingredient variety and container size

- Secondary packaging (cartons/family packs): 20–80 boxes per minute

Key Features:

- Product flexibility: Ability to design various Meal Kits including Mediterranean, Asian, plant-based, and healthy fast-food options

- Freshness & safety: Hygienic process with temperature control and isolated packaging

- Meeting modern consumer trends: Ideal for younger generations and busy families

- Export & online sales potential: Custom packs for retail stores and food delivery platforms

The ready-to-eat Meal Kit market has seen remarkable growth in recent years and is expected to continue its rapid expansion. Combining convenience, freshness, and culinary diversity, this segment offers an attractive investment opportunity in the modern ready-meal industry.

Process Flow Diagram

For more details and expert consultation on setting up a production line, contact us today.

.png)

_800px.png)

_800px.png)

.png)

-copy.png)