Green Coffee Processing and Roasting

The continuous growth of the coffee industry and the rising demand for specialty coffees and diverse brands have made investing in coffee processing and roasting lines one of the most profitable choices.

We provide comprehensive solutions from green coffee processing to roasting, ensuring that coffee beans are handled with the highest quality standards from the moment they enter the facility until they become the final product.

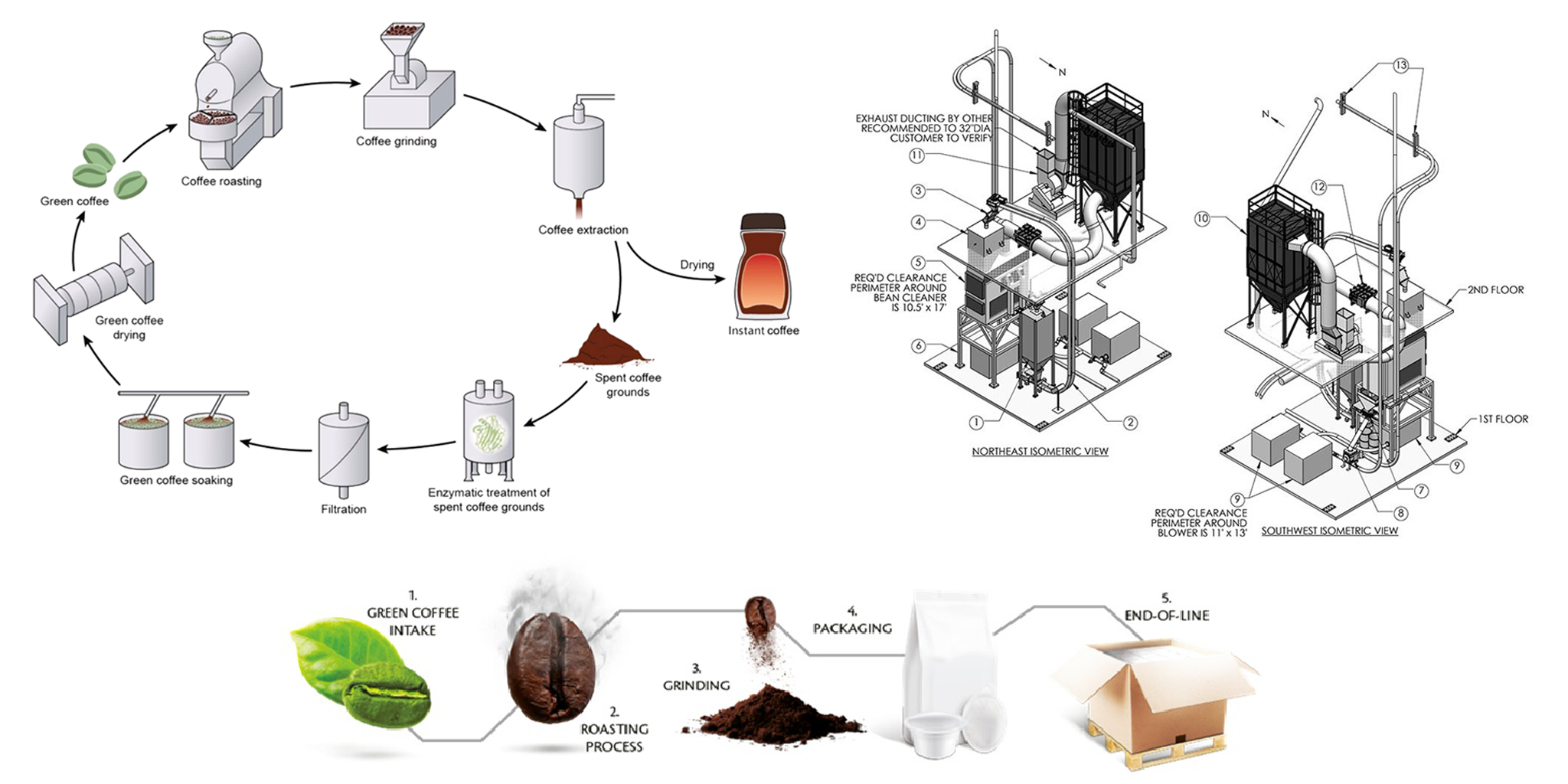

Green Coffee Processing

- Automated unloading and transfer: From 60 kg bags or bulk containers, with no damage to the beans.

- Cleaning and sorting systems: Removal of dust, stones, and impurities to achieve uniform beans.

- Calibration and grading: Ensure quality and consistency in roasting profiles.

- Automated silos and storage: Smart management of volumes from small batches to several tons.

- Initial quality control: Testing and preparation of beans prior to roasting.

Types of Roasters

- Shop models: 35–70 kg/h capacity, ideal for coffee shops, specialty workshops, and cupping centers.

- Industrial models: 100–1,600 kg/h capacity, perfect for mid-sized producers and growing brands.

- Continuous industrial models: 1,000–3,600 kg/h capacity, designed for large-scale production lines requiring high efficiency.

Advantages:

- Complete chain from green bean to final product: Processing, cleaning, storage, and roasting in an integrated system.

- Precise roasting profile control: To achieve the perfect aroma and flavor.

- Consistent and stable quality: In every batch or continuous production.

- Optimized energy consumption and reduced emissions: Through modern technologies.

- High flexibility: Suitable for producing various coffee types, from espresso to filter and instant coffee.

Process Flow Diagram

For consultation on selecting the right production line and investment estimation, contact us today.

.png)

_800px.png)

_800px.png)

.png)

-copy.png)